Last August a group of researchers, technologists, scientists and academics penned an open letter, which was presented at the International Joint Conference on Artificial Intelligence in Buenos Aires, Argentina, warning that progress in artificial intelligence could be harnessed to make killing machines more efficient, but at the same time less accountable – on and off the battlefield. These ominous warnings evoke fears that what has largely been just in the realm of science fiction – from The Terminator to The Matrix – that the “machines could rise up” and threaten mankind.

The fear was summed up by Professor of AI research Toby Walsh, of the School of CSE in UNSW, who said, “most researchers believe that we don’t have the ability to build ethical robots.”

And yet, various military powers around the world – including the United States – are moving forward with programs that would replace human soldiers with robots or other automated systems. In March Deputy Defense Secretary Robert O. Work said that the Pentagon hasn’t “fully figured out” how to best utilize autonomous systems, but is examining this issue.

A Research and Markets report, Global Military Robots Market 2016-2020, forecast that this market will grow at a compound annual growth rate of 9.36 percent. The study noted that currently 87 nations have developed military robots for deployment on the battlefield, and with technological advancement and upgrades these could be more reliable and efficient – yet it could also compensate for military downsizing.

Job Killer?

The World Economic Forum warned that jobs could be lost from the use of robots and automated systems. In January the WEF suggested that the world has entered a “fourth industrial revolution,” one that could lead to a net loss of more than five million jobs in 15 major developed and emerging economies including those of China, the UK and the U.S.

The group noted that automation and other technologies could create 2.1 million new jobs, mainly coming from more specialized areas that require computing, math and engineering backgrounds – but this only offsets the potential 7.1 total jobs that could be lost.

“It is never a positive when we lose jobs and opportunities,” said Scott Steinberg, principal analyst at TechSavvy Global. “But the defense sectors are being put under scrutiny to do more with less, so it may not be affected as greatly as some other sectors.”

Klaus Schwab, founder and executive chairman of the WEF called for urgent and targeted action that would manage near-term transition, and build a workforce that has future proof skills. The defense sector may thus be less hard hit by automation.

“The defense sector continues to look for individuals with greater tech skills,” said Steinberg. “But if it can be done by a robot or a computer, and at a cost savings we can expect to see more automation going forward.”

Taking Soldiers Out of Harm’s Way

The growth in robots and other automated system could fill some job vacancies and possibly even terminate some job opportunities, but that doesn’t mean that “terminators” will be rolling off the assembly line in the near future. In 2012, the U.S. Department of Defense issued a directive that banned the development and use of autonomous and semi-autonomous weapons for 10 years. The United Nations has discussed a similar ban.

Thus in the short term it won’t be killer robots that the U.S. military and other powers will be utilizing, but those that can take over dangerous, or at least mundane, tasks.

“These are the jobs that no one wants to do,” said TechSavvy Global’s Steinberg. “There are a number of tasks including test trials in hazardous environments or situations, and automated systems could take over those. These are the situations where you should expect to see more and more automation as contractors look to provide cost effective solutions.”

The military could also take a cue from the civilian automotive market, where companies from Ford Motors to tech giant Google have been testing autonomous vehicles. Recently several international truck manufacturers took part in the first of its kind European Truck Platooning Challenge, while the U.S. military has been testing similar solutions. For the military this could take soldiers out of harm’s way in hot zones – such as those in Afghanistan and Iraq where there is a constant threat of IEDs.

“Most of the automation we’re seeing is in logistics more than combat,” said Dr. Satyandra K. Gupta, research professor at the University of Maryland Department of Mechanical Engineering. “Defense has a huge logistic supply chain that isn’t that different from other industries. Automation could take the human element out of these mundane and even dangerous situations.”

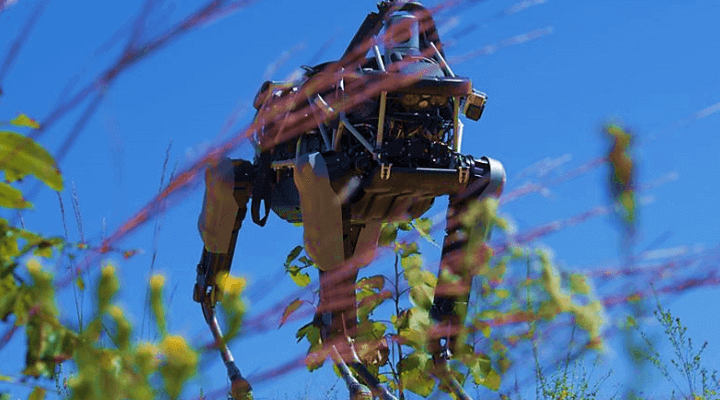

Smaller robots and semi-autonomous devices are being used on the battlefield, but not as robot warriors.

“Mine and explosives detection/removal are popular scenarios, as are various surveillance applications,” noted Charles King, principal analyst at Pund-IT.

Many of these devices still require human operators, so the level of autonomy is limited.

“We’re still years or even decades away from seeing autonomous robotic devices fulfill combat roles,” added King. “We’re reaching a point where robotic technologies will take on an increasing range of military tasks and roles.”

Part of this is due to technological advances coming from development of autonomous vehicles, but said King, “it also relates to the rapidly declining costs of these technologies. With the U.S. military downsizing, finding cost-effective alternatives for roles currently performed by live soldiers is a critical task.”

Doing More With Less

For the military, automation could directly help offset the reduced number of people in uniform as the military downsizes. Not only could this mean driverless trucks, but automated systems has already meant smaller crew sizes on ships. This reduces the number of sailors that might be in harm’s way, but can also allow the crew to have a few more creature comforts or at least a bit more space.

“The military is using many forms of automation such as the Zumwalt class of destroyer, which is the size of a cruiser and has a crew of 140 versus the much smaller Burke class destroyer with a typical complement of 303 personnel,” said Wayne Plucker, aerospace and defense director at Frost & Sullivan. “This is possible with automated guns and other fire control systems as well as automated fire fighting and ship’s handling.”

Going forward we could see more and more positions on ships, planes and even at bases that are automated.

However, “It will be a matter of time before we understand if this is successful,” added Steinberg.

Military Logistics

The military and defense contractors alike each require huge logistical support, and automation could bring further costs savings as it has for some industries.

“Robots can be used in a warehouse situation, where you can save on the energy bill as you don’t have to maintain temperature and conditions required when you have human workers,” added Gupta.

“The massively complex supply chain activities that are often required to support military efforts also offer numerous situations where robotic technologies could be used to speed or enhance various processes,” said Pund-IT’s King.

Automation is also being utilized in production lines, where defense contractors are following other industries, but just as with combat scenarios the human isn’t fully being replaced.

“Manufacturers are using automatic welders, riveters, and automated test equipment,” said Frost & Sullivan’s Plucker. “Many types of routine tasks can be conducted using automated equipment or equipment that is only partly monitored. The tough decisions will be where the ‘man in the loop’ becomes necessary.”